The Significance of Clear Forklift Truck Safety Signs in Storehouses

The Significance of Clear Forklift Truck Safety Signs in Storehouses

Blog Article

Ideal Practices for Displaying Forklift Truck Safety Signs in Industrial and Storage Facility Setups

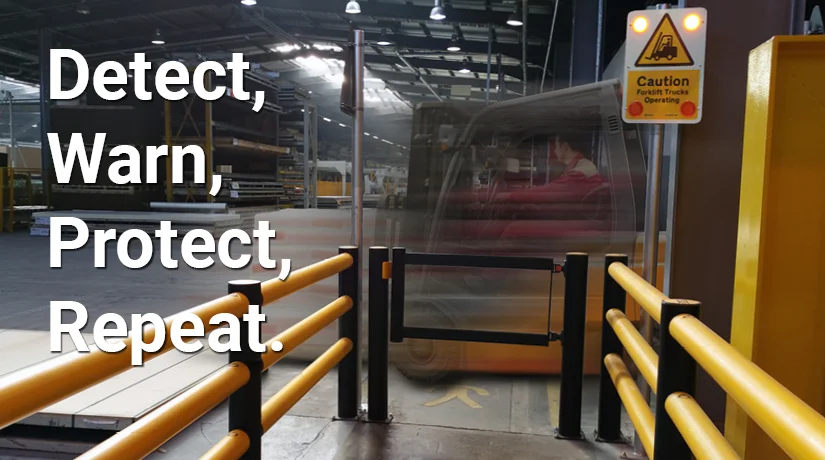

The implementation of efficient forklift truck safety signs is vital in commercial and storage facility settings, where the threat of mishaps can dramatically influence both workers and procedures. Trick factors to consider such as visibility, positioning techniques, and adherence to regulative standards are crucial for making best use of the efficiency of these signs. Additionally, the ongoing maintenance and periodic evaluation of signage can additionally boost precaution - Forklift Truck Safety Signs. The actual obstacle lies in balancing these aspects to promote not just compliance but likewise an aggressive society of security. What certain approaches can organizations adopt to ensure their safety signs really serves its function?

Importance of Safety Signs

The value of safety signage in environments where forklift vehicles run can not be overemphasized, as these signs play an essential role in avoiding accidents and ensuring the safety and security of workers. Efficient safety signage serves as a vital interaction tool, conveying vital info about prospective risks connected with forklift operations. This consists of cautions concerning pedestrian zones, rate restrictions, and designated forklift paths, which are important for keeping an arranged and risk-free workplace.

Properly shown security indications can improve situational recognition amongst workers, reminding them of the threats included in their surroundings. They give clear directions on safe practices, such as wearing ideal personal protective tools (PPE) and sticking to functional standards. Additionally, safety and security signs adds to compliance with governing requirements, aiding organizations prevent fines and advertise a culture of security - Forklift Truck Safety Signs.

In addition to their precautionary role, security indications cultivate a sense of responsibility amongst employees. When employees understand safety procedures and the possible effects of overlooking them, they are more probable to take positive actions to protect themselves and their colleagues. As a result, spending in top quality security signs is crucial for any workplace where forklift trucks function.

Trick Visibility Elements

Efficient exposure is critical in making sure the security of both forklift operators and pedestrians in hectic job settings. To accomplish this, a number of essential exposure elements have to be thought about when creating and putting security signs.

First, the size and typeface of the message on the indicator play a crucial role. Bigger typefaces improve readability from a distance, allowing people to quickly understand the message. In addition, using bold and clear fonts can dramatically improve legibility under various lights conditions.

Efficient Positioning Strategies

Indication placement substantially influences their performance in communicating security messages within forklift operations. To maximize presence and comprehension, indicators should be tactically positioned in locations where forklift task prevails. Key locations include intersections, blind spots, and near loading and discharging zones, where operators and pedestrians interact frequently.

Elevation is an additional critical aspect; indications ought to be put at eye degree Visit Website to ensure they are easily seen by both forklift drivers and ground employees. Furthermore, using contrasting shades and clear graphics will boost presence, particularly in low-light conditions or high-traffic locations.

Think about the flow of traffic when figuring out placement. Indications must be placed to assist operators securely and successfully with the work area, minimizing the threat of accidents. Routine analyses must be conducted to ensure that indicators remain unblocked by equipment or stock, as changing designs can lessen their efficiency.

Incorporating comments from staff members relating to indicator placement can likewise cause enhancements. Involving staff in this process cultivates a culture of security and recognition, eventually adding to a much more protected workplace. By executing these efficient positioning approaches, companies can improve communication and adherence to safety and security protocols.

Compliance With Rules

Making sure conformity with laws is essential for preserving a safe workplace in forklift procedures. Regulative bodies such as the Occupational Security and Health Administration (OSHA) and the American National Standards Institute (ANSI) establish guidelines that dictate the correct use safety and security indications. Adherence to these policies not only promotes safety yet additionally alleviates the risk of penalties and lawful obligations.

Forklift safety and security indicators need to be clearly noticeable, readable, and strategically positioned according to governing needs. These indicators need to make use of standardized symbols and shade codes to convey critical details successfully. Visit This Link Yellow suggests care, while red signals risk, making certain that workers can promptly translate the indicators in high-stress circumstances.

Organizations needs to carry out routine audits to validate that all security signage satisfies current legal standards. Maintaining abreast of changes in guidelines is also critical, as non-compliance can result in substantial functional interruptions. By making certain that forklift safety indications stick to mandated guidelines, business promote a society of security understanding amongst employees, thus improving total workplace safety and security and efficiency. This dedication to conformity is an essential element of an efficient safety and security management program.

Regular Upkeep and Updates

Preserving and updating forklift safety and security indications is important for ensuring that they continue to be reliable and pertinent in the workplace. Normal assessments should be performed to evaluate the problem of safety indicators, as direct exposure to harsh commercial environments can cause fading, damage, or obsolescence. Indications that are no more readable or that include outdated details can considerably threaten safety methods.

It is important to develop a routine upkeep schedule that consists of examining the exposure and quality of all safety signage. Any kind of signs that are used, damaged, or misaligned ought to be without delay replaced or repositioned to keep their performance. Additionally, as regulations and safety criteria evolve, it is important to upgrade signs to reflect current methods and conformity needs.

Involving employees in safety and security training sessions can likewise reinforce the importance of preserving and updating safety signs. This not just ensures that everybody is conscious of the indicators' definitions yet also promotes a culture of security within the work environment. By focusing on normal upkeep and updates, companies can develop a much safer setting and boost the total efficiency of their forklift safety and security signs.

Verdict

Finally, the implementation of best techniques for displaying forklift vehicle safety my review here and security indicators is important for enhancing workplace safety in commercial and stockroom atmospheres. By prioritizing visibility, employing reliable positioning approaches, making sure compliance with guidelines, and devoting to routine maintenance, organizations can dramatically lower the danger of mishaps. Such steps not just connect threats successfully however also cultivate a society of safety that profits all staff members associated with forklift operations.

Report this page